GOTS- (Global Organic Textile Standard)

The Global Organic Textile Standard (GOTS) is recognised as the world’s leading processing standard for textiles (clothing, home textiles, personal care products and food contact textiles) made from certified organically produced raw materials.

The standard covers the processing, manufacturing, packaging, labelling, trading and distribution of all textiles made from at least 70% certified organic fibres. There are two GOTS label-grades: ‘organic’

requiring a minimum of 95% organic fibres and ‘made with organic materials’ requiring at least 70% organic fibres.

THE COMPANY BENEFIT FROM BEING GOTS-CERTIFIED

- Risk Reduction – the strict criteria of GOTS act as a comprehensive risk management instrument for your supply chain.

- Credibility – third-party certification serves as independent external verification along your entire supply chain

- Traceability – fibre material in the GOTS system can be traced to its origin, ensuring that final products have been manufactured following strict social and environmental criteria.

- Productivity – GOTS requirements result in improved social and environmental efficiency.

- Innovation – GOTS certification provides added value over conventional products and can help your company access new markets.

GRS (Global Recycle Standard)

The Global Recycled Standard (GRS) is a voluntary product standard for tracking and verifying the content of recycled materials in a final product.

The GRS label applies to companies in the textile sector with activity in spinning knitting, printing, stitching, ginning, weaving and dyeing, but also to recyclers, distributors and brands who want to have their recycled products and their responsible practices recognised by an international label.

You can use the GRS as a business-to-business tool for any products that contain at least 20% recycled content, but if you want to use consumer-facing labeling, the product must contain at least 50% recycled content.

Benefits of GRS certification include:

- Reducing your environmental impact,

- Meeting customer demands for sustainable products

- Improving supply chain transparency, and

- Gaining a competitive advantage in the market.

OCS (Organic Content Standard)

The Organic Content Standard aims to increase organic agricultural production. The Organic Content Standard (OCS) is a voluntary global standard that sets the criteria for third-party certification of organic materials and chain of custody.

The goal of the Organic Content Standard (OCS) is to increase organic agriculture production.

The OCS aims to deliver this goal through three key objectives:

- Provide the industry with a tool to verify the organically grown content of the products they purchase.

- Provide companies with a trusted tool to communicate organically grown content claims to the industry.

- Provide organic farmers with broad access to the global organic market for their products.

RCS- Recycle Claim Standard

The Recycled Claim Standard is intended for use with any product that contains at least 5% Recycled Material. Each stage of production is required to be certified, beginning at the recycling stage and ending at the last seller in the final business-to-business transaction.

Benefits of Recycling Claim Standard

- Recycling reduces waste sent to landfills and incinerators.

- Recycling prevents pollution.

- Recycling conserves natural resources.

- Recycling conserves energy.

- Recycling creates jobs, producing economic benefits.

RWS- Responsible Wool Standard

The Responsible Wool Standard (RWS) is an industry tool designed to recognize the best practices of farmers, ensuring that wool comes from farms with a progressive approach to managing their land, and from sheep that have been treated responsibly.

Key Points in the RWS

- Protecting Animal Welfare

- Preserving Land Health

- Protecting Social Welfare

- Credible Certification

- Stakeholder Engagement

- Chain of Custody

FSSC 22000

The FSSC 22000 program is a risk-based certification program that helps food producers reduce the risk of providing an unsafe product to consumers and maintain an effective, tailored food safety program in a dynamic regulatory environment.

FSSC 22000 Operational Benefits

- Demonstrates your commitment by providing the best quality food and food-related materials and services.

- Gain confidence of your customers, vendors and stakeholders.

- Accelerate the growth with standard risk management.

- Internal management efficiency and hence, save time and resources.

- Continual improvement in the performance.

- Easily avoid and manage food hazards and risks.

- Increase operational efficiency in the organization.

- Improved food safety management system.

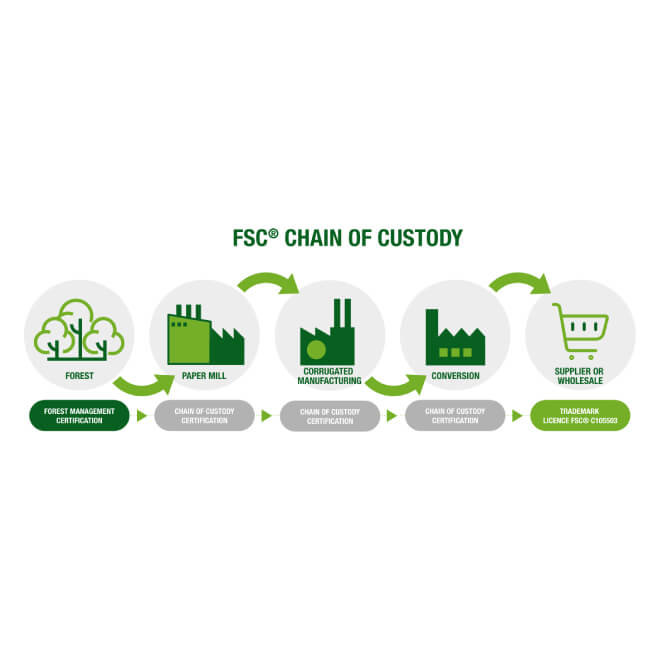

FSC-COC (Forest Stewardship Council- Chain of Custody)

Chain of custody certification is how the Forest Stewardship Council (FSC) verifies that forest-based materials produced

according to our rigorous standards are credibly used along the product’s path from the forest to becoming finished goods.

Process:

FSC chain of custody certification verifies that FSC-certified material has been identified and separated from non-certified and uncontrolled material as it makes its way along the supply chain, from the forest to the market.

Key Benefit of FSC COC

- Brand recognition

- Access to Markets

- Credibility

- High environmental standards

- Protection of workers’ rights

- Community Engagement

SQP (Supplier Qualification Program)

SQP Program presents an effective solution for retailers, brands, and buyers to evaluate supplier performance and promote continuous improvement. It provides a standard that shows improvement by ensuring supplier’s production processes have the controls which are required to mitigate risk.

Requirements:

- Management Commitment and Continual Improvement

- Risk Management Systems

- Quality Management Systems

- Site and Facilities Management

- Product Control

- Product Testing and Product Claims

- Process Control

- Personnel Training and Competency

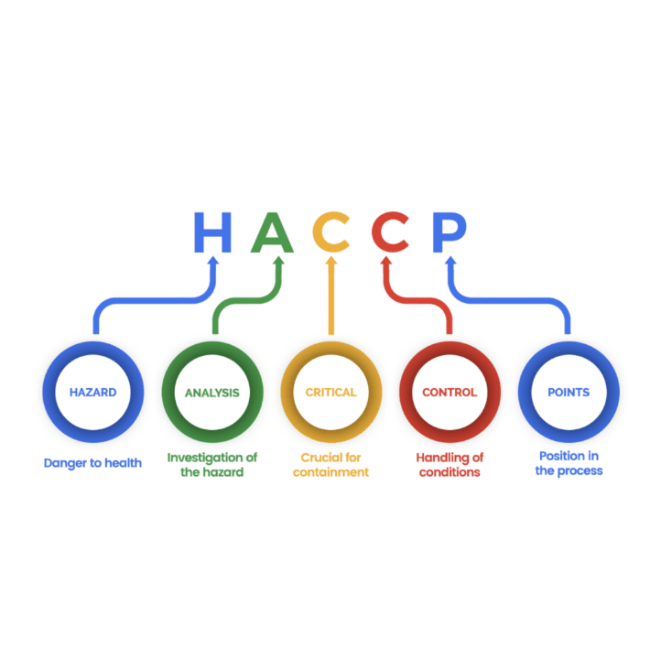

HACCP – Hazard Analysis Critical Control Point

Hazard Analysis Critical Control Points (HACCP) is a system which provides the framework for monitoring the total food system, from harvesting to consumption, to reduce the risk of food borne illness. The system is designed to identify and control potential problems before they occur.

Seven basic principles are employed in the development of HACCP plans that meet the stated goal.

These principles include:

- Conduct Hazard analysis,

- Determine and identified the CCP (Critical Control Point),

- Establishing critical limits,

- Establish a system to monitor control of the CCP.

- Establish the corrective action to be taken when monitoring indicates that a particular CCP is not under control.

- Establish procedures for verification to confirm that the HACCP system is working effectively. and

- Establish documentation concerning all procedures and records appropriate to these principles and their application.

KOSHER Certification

Kosher Certification is the stamp of kosher approval by a rabbinic Agency verifying they have checked the products ingredients, production facility and actual production to ensure all ingredients, derivatives, tools and machinery have no trace of non-kosher substances.

Requirements

- SOURCE OF FOOD

- Foods of Animal Origin

- Genetically Modified Product

- Packaging Materials

- Food Services and Facilities

- Food Processing

- Machines, Tools, Production Lines

- Storage, Display, Presentation and Transportation

- Hygiene, Sanitation and Food Safety

- Validation and Validation

- Identification and Traceability

- Market Supply

- Packaging and Labelling

- Legal Requirements

- Logo Usage

GMP certificate

Good manufacturing practice (GMP) is a system for ensuring that products are consistently produced and controlled according to quality standards. It is designed to minimize the risks involved in any pharmaceutical production that cannot be eliminated through testing the final product.

The 5 P’s of GMPs

Products

Constant testing, comparison, and quality assurance are crucial steps in the product lifecycle to ensure they meet the desired standards before reaching consumers. All primary materials, including raw products and other components, should have clearly defined specifications at every production phase. Standard methods for packing, testing, and allocating sample products should be adhered to, ensuring consistency and quality at all times.

Processes

Clear, consistent, and well-documented processes are essential to effective GMP. These documented processes should be made accessible to all employees, and regular evaluations should be conducted to ensure compliance and alignment with the organization’s quality standards.

Procedures

Procedures, defined as a set of guidelines for performing a critical process or a part of a process, play a pivotal role in achieving consistent results. All employees must be familiar with these procedures and follow them diligently. Any deviation from standard procedures should be immediately reported, thoroughly investigated, and adequately addressed to prevent compromise on product quality.

Premises

The condition and maintenance of premises directly influence product quality. Premises should be maintained clean at all times to prevent cross-contamination, accidents, or other undesirable outcomes. Equipment placement, proper storage, and regular calibration are crucial to ensure their optimal functionality and reliability, thereby producing consistent results and preventing equipment failure risks.

People

All employees are expected to strictly follow manufacturing processes and regulations. To ensure this, we recommend regular GMP training for all employees to enhance their understanding of their roles, responsibilities, and the importance of their contributions to product quality and safety. Regular performance assessments further aid in boosting productivity, efficiency, and competency.

HIGG Index – FEM (Facility Environmental Module)

Focus areas:

- Environmental Management Systems

- Emissions to Air (if applicable)

- Water Use

- Wastewater

- Energy Use and Greenhouse Gas Emissions

- Waste Management

- Procuring, storage, usage and disposal of chemicals.

HIGG Index – FSLM (Facility Social & Labour Module)

FSLM allows facilities to evaluate their social labour performance and practices, benchmark against their peers, and identify areas of leadership or opportunities for improvement.

Impact areas it measures:

- Human Resource activity.

- Total working/ operational hours of employees.

- Minimum wages as per legal requirement & benefits.

- No discrimination with employees.

- Labour union & involvement.

- Operational Health & Safety.

- Implemented Management Systems.

- Social corporate responsibility.

OEKO-TEX STANDARD

Oeko-Tex certifies non-hazardous end-products and all of their components. Products that carry the Standard 100 label have been tested and proven free of harmful levels of toxic substances.

Oeko-Tex awards

Oeko-Tex Standard 100

OEKO-TEX® STANDARD 100 is a label for textiles tested for harmful substances. It sets the benchmark for textile safety, from yarn to finished product. Every item bearing the STANDARD 100 label is certified as having passed safety tests for the presence of harmful substances.

Oeko-Tex Made in Green

Textiles and leather items carrying the OEKO-TEX® MADE IN GREEN label are produced more sustainably in socially responsible workplaces. Customers purchase them with confidence that they are traceable and tested for harmful substances. This label supports both better working conditions and a healthier planet.

Oeko-Tex Leather Standard

Whether shoes, clothes, accessories or sofas, an item bearing the OEKO-TEX® LEATHER STANDARD label is a better and safer choice. Leather that meets this standard has been scientifically tested for harmful substances.

Oeko-Tex Eco Passport

Chemicals, colorants and auxiliaries that meet the OEKO-TEX® E CO PASSPORT standard have been tested and analysed against strict criteria, for a lower environmental impact. By deploying greener chemistry, your company supports cleaner, safer textile and leather products and production.

Oeko-Tex STeP

OEKO-TEX® STeP certification sets the highest standards for both social and environmental aspects of textile and leather production, as well as for industrial laundries. This certification is a sign of responsibility towards employees and the environment, and supports a company’s journey towards more sustainable production.

OEKO-TEX® ORGANIC COTTON

OEKO-TEX® ORGANIC COTTON for a caring approach to our environment and your health. Our ORGANIC COTTON certification offers verification from farm to product. Products bearing this label have been manufactured without the use of GMOs and tested for pesticides and other harmful substances.